Mach3 Serial Port Plugin Container

This is an ongoing development. I've been working on an Arduino-based Torch Height Controller for a while. I currently have the hardware design stable and functional and mostly complete THC code.

1-1 Chapter 1 Introduction to CNC Systems This chapter introduces you to terminology used in the rest of this manual and explains the purpose of. If Mach3 is not configured with the correct information your TB6560 Driver board won't function. Looking at the line 'ECP Printer Port (LPT1)' tells us 2 things, in your computers BIOS the printer port is set to the ECP protocol, and, it is Port 1 (from LPT1) on the PC's serial/parallel bus.

While there is a Windows-based app to control the THC - I've recently been working on a Mach Plugin. This is my first Mach Plugin. I have initial functionality working.

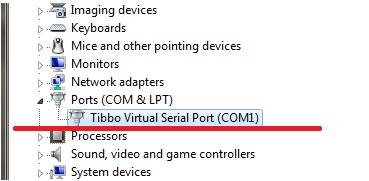

The plug-in communicates with the THC over a user configurable COM port. It allows setting the THC operating mode, setting the target cutting voltage and monitoring the operation. The plugin spawns a new thread for handling the serial port communications.

It also gives the ability to set Mach's 'THC Mode' to ON when starting. (There is a configuration option to stop and restart the serial thread - that doesn't work yet. If you change the serial port you have to stop and restart Mach.) Software source code, hardware design information and a user guide is available on github under the 'regeg/ArduinoTHC' project. Video of the test cuts with steel on a steep incline can be seen at: All of the history of the development and lots of voltage captures of cutting are on the Plasma forum at the Everlast Generators site. I'd really like to get people building the THC and contributing to the project.

I've been in a very similar situation. X3 reunion cockpit mod download. Designed a microcontroller based board for marking hole centres. It's a closed loop control that monitors when the torch has fired or monitors current level (user selectable).

Then a user adjustable delay to determine the size of the crater in the top of the metal. So even if your cut current is set at 100 amps, the hole marking can be done at 15 amps. Works absolutely great and I have complete control over the size of the tiny divot in the top of the metal. Even post cut airflow on or off makes no difference because this is a closed loop control monitoring what the torch is doing. I was looking at turning it into a product but basically got no interest either, so now just use it for myself (quite often). Samson sound deck pro shop. Wouldn't want to be without it.